一、概述/ Summary

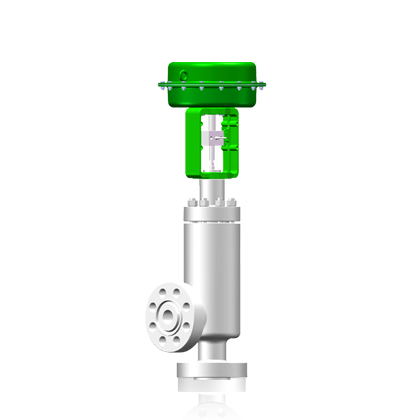

加氢在炼化、煤化工行业中已成为普遍采用的流程。加氢装置工艺要求的技术难点在于高温高压介质的测量和控制。包括高温高压介质的流量和压力控制。控制阀门在高压差、汽蚀、冲蚀等严酷工况条件下,存在寿命短、阀杆易断裂、阀芯易脱落严重问题。汉德多级降压高压角阀采用多级节流形式来分摊压差,减少了气蚀、冲蚀、挠流破坏,大大提高了调节阀的使用寿命,角型结构,阀体流路简单,阻力小,特别适用于高粘度,含有悬浮物和颗粒状介质流体的调节,可避免结焦、粘结、堵塞。

Hydrogenation has been widely used in refining and coal chemical industry. The technical difficulty of hydrogenation unit is the measurement and control of high temperature and high pressure medium. Including the flow control of high temperature and high pressure medium. Under severe working conditions such as high pressure difference, cavitation and erosion, the control valve has some serious problems, such as short service life, easy fracture of valve stem and easy falling off of bushing. It is suitable for high-pressure valve body with high-pressure, low-pressure, high-pressure, high-pressure, high-pressure, high-pressure valve body.

二、结构及材质/ Structure and material

序 | 名称/ Name | 材质/material |

1 | 阀体/Body | 碳钢、铬钼钢、高温不锈钢等 |

2 | 金属缠绕垫/ Metal winding gasket Metal winding gasket Metal winding gasket | SS304/316L+柔性石墨 |

3 | 阀座/ Seat | SS316/PTFE/WC |

4 | 阀笼/ Valve cage | 17-4PH |

5 | 密封圈/ seal ring | PTFE+Elgiloy |

6 | 密封圈压环/ Seal ring pressure ring | SS316 |

7 | 金属缠绕垫/ Metal winding gasket Metal winding gasket | SS304+柔性石墨 |

8 | 阀盖/ Valve cover | 碳钢 A216 WCC/不锈钢 |

9 | 平垫/ Flat pad | 碳钢/不锈钢 |

10 | 六角螺母/ Hexagon nut | 碳钢/不锈钢 |

11 | 双头螺栓/ Stud bolt | 碳钢/不锈钢 |

12 | 阀芯组件/ Spool assembly | / |

13 | 填料垫片/ Packing gasket | SS304 |

14 | 填料/ filler | PTFE/石墨 |

15 | 填料压套/ Packing press sleeve | SS304 |

16 | 填料压盖/ Packing press sleeve | 20# |

17 | 双头螺栓/ Stud bolt | SS304 |

18 | 六角螺母/ Hexagon nut | SS304 |

19 | 六角头螺栓/ Hexagon headed bolt | 碳钢/不锈钢 |

20 | 气动执行器/ Pneumatic actuator | 气缸/薄膜 |

三、主要技术性能/ Main technical performance

序号 | 类别 | 参数和性能 | 序号 | 类别 | 参数和性能 |

1 | 公称通径/ body size | 1〃—8〃/ DN25—DN200 | 7 | 驱动方式 | 气动、液动 |

2 | 压力等级/ Press.Rating | class150—class2500/ PN20—PN420 | 8 | 流量特性 | 线性、快开 |

3 | 适用介质/state | 重油、渣油、煤焦油、蒽油等 | 9 | 执行机构 | 气动薄膜、活塞式气缸 |

4 | 适用温度 | -30~550℃ | 10 | 附件 | 减压阀、过滤器、定位器、气源放大器、气锁阀、快速排气阀 |

5 | 泄漏等级 | ANSI CLASS V Ⅵ | 11 | 定位器性能 | 定位器防爆级别Exd ⅡCT4 Exd ⅡCT6;防护级别IP65 |

6 | 连接方式 | RFF, RTJ等 | 12 | 可调比 | 50:1 |

四、特点/ Characteristic:

1、消除空化现象。阀内件设计成多阶流动通道,分为多个阶段将压力降至目标值,不允许介质的局部压力降至介质的饱和蒸汽压力以下,这些主动同步节流措施,避免了任何单个阶段承受全部压降,从而起到了消除空化现象。

Eliminate cavitation. The valve internals are designed as multi-stage flow channels, which are divided into several stages to reduce the pressure to the target value, and the local pressure of the medium is not allowed to drop below the saturated steam pressure of the medium. These active synchronous throttling measures can avoid all pressure drop in any single stage, thus eliminating cavitation phenomenon.

2、抗污性强。阀内件与阀体间的宽流道设计,允许较大的固体颗粒自由通过,而不会造成任何堵塞或流通能力损失,确保了系统连续有效的运行,是在脏、污介质中应用的一个行之有效的解决方案。

Strong antifouling property. The wide flow passage design between the valve internals and the valve body allows larger solid particles to pass freely without causing any blockage or loss of flow capacity, ensuring the continuous and effective operation of the system. It is an effective solution for the application in dirty and dirty media.

3、粗阀塞导向。阀塞通过与表面硬化后的阀笼的间隙配合,全行程提供导向,最大限度的减少振动,产生良好的稳定性,有助于高压差介质平稳的通过阀内节流元件,提高了系统的可靠性。

Coarse plug guide. The valve plug can match with the clearance of the valve cage after surface hardening to provide guidance for the whole stroke, minimize the vibration and produce good stability, which is helpful for the medium with high pressure difference to pass through the throttle element in the valve smoothly and improve the reliability of the system.

4、多种阀内件型式可选。标配的内件分为3阶(级)、4阶(级)、6阶(级)具有不同的降压比,可覆盖绝大多数高压差的降压要求,本公司还可以提供特殊的分级方案,以满足特定的应用要求。阀塞分为平衡式和不平衡式设计, 以便灵活的适应各种工况。

A variety of trim types are available. The standard internal parts are divided into three levels (level), four levels (level) and six levels (level), with different pressure drop ratios, which can cover most of the pressure drop requirements of high pressure difference. The company can also provide special grading scheme to meet specific application requirements. Valve plug is divided into balanced and unbalanced design, in order to flexibly adapt to various conditions.

5、阀座防冲刷保护设计。在行程开度极小时,阀内件节流窗口设计成重叠,确保高流速介质远离阀座,避免了阀座的冲蚀,从而延长了高压差条件下整阀的使用寿命。

Anti erosion protection design of valve seat. When the stroke opening is very small, the throttle windows of the valve internals are designed to overlap, so as to ensure that the medium with high flow rate is far away from the valve seat and avoid the erosion of the valve seat, thus prolonging the service life of the whole valve under the condition of high pressure difference.

6、可靠的密封性能。阀座密封泄漏等级符合IEC534-4和ANSI/FCI 70.2 V 级标准要求,软密封阀座可达到VI级标准要求。其中专利设计:在软密封阀座外表设计金属滑动保护环,保护软阀座不受挤压,并在紧急情况时作为备用阀座。 可配备气动元件,作为紧急切断装置使用。

Reliable sealing performance. The leakage grade of the valve seat can meet the requirements of iec534-4 and ANSI / FCI 70.2 V, and the soft sealing valve seat can meet the requirements of vi. Among them, the patented design: metal sliding protection ring is designed on the surface of the soft sealing valve seat to protect the soft valve seat from extrusion, and it can be used as a spare valve seat in case of emergency. Can be equipped with pneumatic components, as an emergency cut-off device.

7、维护简单。阀内件采用无螺纹设计,可从顶部入口快速更换阀内件,一体式衬套和阀座减少了部件的数量,简化了装配和拆卸流程。

Simple maintenance. The valve trim adopts non threaded design, which can quickly replace the valve trim from the top inlet. The integrated bushing and seat reduce the number of parts and simplify the assembly and disassembly process.

8、符合NACE 和 PED 标准要求。阀可按NACE标准MR 0103中的规定设计及加工,用于有一定腐蚀性介质的场合。 也可按标准MR0175 - 2003或 ISO 15156 的要求提供,设计符合PED指令的要求。

Meet the requirements of NACE and ped standards. The valve can be designed and manufactured according to the provisions of NACE standard MR 0103. It can be used in some corrosive media. It can also be provided according to the requirements of MR0175-2003 or ISO 15156, and the design meets the requirements of ped.

五、阀门结构尺寸和重量/ Valve structure size and weight

(一)阀门结构尺寸/ Valve structure size

尺寸(寸) | A(mm) | B(mm) | ||||||||||||||||

阀盖标准型/Standard Bonnet | 阀盖加长型/Extension Bonnet | ANSI Class 600-900 | ANSI Class 1500 | ANSI Class 2500 | ANSI Class 600 | ANSI Class 900 | ANSI Class 1500 | ANSI Class 2500 | ||||||||||

ANSI Class 600-2500 | ANSI Class 600-2500 | |||||||||||||||||

3&4阶 | 6阶 | 3&4阶 | 6阶 | BW | SW&THD | BW | SW&THD | BW | SW&THD | RF | RTJ | RF | RTJ | RF | RTJ | RF | RTJ | |

1 | 181 | 216 | 283 | 318 | 98 | 98 | 98 | 98 | 108 | 108 | 146 | 146 | 146 | 146 | 146 | 146 | 154 | 154 |

1.5 | 181 | 216 | 283 | 318 | 118 | 118 | 118 | 118 | 130 | 130 | 156 | 156 | 156 | 156 | 156 | 156 | 179 | 181 |

2 | 276 | 330 | 406 | 460 | 187 | 187 | 187 | 187 | 187 | 187 | 187 | 189 | 187 | 189 | 187 | 189 | 207 | 208 |

3 | 358 | 441 | 503 | 585 | 221 | / | 230 | / | 249 | / | 221 | 222 | 221 | 222 | 230 | 232 | 249 | 251 |

4 | 405 | 506 | 530 | 632 | 256 | / | 265 | / | 287 | / | 256 | 257 | 256 | 257 | 265 | 267 | 368 | 373 |

6 | 506 | 645 | 607 | 747 | 384 | / | 384 | / | 410 | / | 384 | 386 | 384 | 386 | 384 | 389 | 410 | 416 |

8 | 607 | 768 | 696 | 857 | 416 | / | 416 | / | 511 | / | 457 | 459 | 457 | 459 | 486 | 490 | 511 | 519 |

(二)标准阀盖系列重量(Kg)/Series Cast Angle Body with Standard Bonnet

规格/寸 | 3&4阶重量(公斤)/ Weights (kg) | 6阶重量(公斤)/ Weights (kg) | ||||||||||||||

ANSI Class 600-1500 | ANSI Class 2500 | ANSI Class 600 | ANSI Class 900 | ANSI Class 1500 | ANSI Class 2500 | ANSI Class 600-1500 | ANSI Class 2500 | ANSI Class 600 | ANSI Class 900 | ANSI Class 1500 | ANSI Class 2500 | |||||

BW | SW&THD | BW | SW&THD | RF/ RTJ | RF/ RTJ | RF/ RTJ | RF/ RTJ | BW | SW&THD | BW | SW&THD | RF/ RTJ | RF/ RTJ | RF/ RTJ | RF/RTJ | |

1 | 19 | 20 | 20 | 20 | 23 | 27 | 27 | 30 | 45 | 46 | 46 | 46 | 53 | 62 | 62 | 69 |

1.5 | 21 | 22 | 22 | 22 | 27 | 32 | 32 | 43 | 49 | 51 | 52 | 52 | 64 | 74 | 74 | 98 |

2 | 72 | 74 | 78 | 80 | 78 | 89 | 90 | 106 | 169 | 174 | 183 | 187 | 182 | 208 | 208 | 244 |

3 | 104 | / | 123 | / | 113 | 122 | 135 | 184 | 264 | / | 310 | / | 284 | 304 | 331 | 443 |

4 | 191 | / | 215 | / | 210 | 218 | 234 | 340 | 481 | / | 543 | / | 522 | 540 | 576 | 815 |

6 | 467 | / | 505 | / | 517 | 538 | 570 | 767 | 1214 | / | 1355 | / | 1322 | 1369 | 1442 | 1934 |

8 | 939 | / | 1099 | / | 1030 | 1075 | 1148 | 1521 | 2382 | / | 2882 | / | 2583 | 2682 | 2843 | 3814 |

(三)加长阀盖系列重量(Kg)Series Cast Angle Body with Extension Bonnet

规格/寸 | 3&4阶重量(公斤)/ Weights (kg) | 6阶重量(公斤)/ Weights (kg) | ||||||||||||||

ANSI Class 600-1500 | ANSI Class 2500 | ANSI Class 600 | ANSI Class 900 | ANSI Class 1500 | ANSI Class 2500 | ANSI Class 600-1500 | ANSI Class 2500 | ANSI Class 600 | ANSI Class 900 | ANSI Class 1500 | ANSI Class 2500 | |||||

BW | SW&THD | BW | SW&THD | RF/ RTJ | RF/ RTJ | RF/ RTJ | RF/ RTJ | BW | SW&THD | BW | SW&THD | RF/ RTJ | RF/ RTJ | RF/ RTJ | RF/RTJ | |

1 | 22 | 23 | 22 | 23 | 26 | 29 | 29 | 33 | 23 | 24 | 24 | 24 | 27 | 31 | 31 | 34 |

1.5 | 23 | 24 | 24 | 24 | 30 | 34 | 34 | 45 | 25 | 25 | 26 | 26 | 31 | 36 | 36 | 47 |

2 | 80 | 82 | 86 | 88 | 86 | 98 | 98 | 113 | 85 | 86 | 91 | 93 | 90 | 102 | 102 | 119 |

3 | 110 | / | 130 | / | 120 | 129 | 141 | 190 | 125 | / | 147 | / | 135 | 144 | 156 | 207 |

4 | 201 | / | 225 | / | 220 | 228 | 244 | 349 | 230 | / | 255 | / | 248 | 256 | 272 | 381 |

6 | 482 | / | 519 | / | 532 | 553 | 585 | 782 | 566 | / | 630 | / | 615 | 636 | 669 | 892 |

8 | 971 | / | 1131 | / | 1062 | 1107 | 1180 | 1554 | 1113 | / | 1339 | / | 1204 | 1249 | 1322 | 1762 |

六、额定流量系数CV值与行程/ Rated flow coefficient CV value and stroke

(一)标准的额定流量系数- 3-阶 流量特性:近似线性

公称通径 | 阀座直径 | 额定行程 | 阀内件型式C | 最小额定流量系数Cv | ||||

Inches | DN | Inches | mm | Inches | mm | Cv | FL | |

1 | 25 | 0.7 | 17.8 | 0.25 | 6.35 | 2 | 0.98 | 0.05 |

1.5 | 40 | 1 | 25.4 | 0.25 | 6.35 | 3.8 | 0.98 | 0.1 |

2 | 50 | 1.5 | 38.1 | 0.38 | 9.65 | 9 | 0.98 | 0.15 |

3 | 80 | 2.25 | 57.2 | 0.62 | 15.7 | 20 | 0.98 | 0.25 |

4 | 100 | 2.88 | 73.2 | 0.75 | 19.1 | 34 | 0.98 | 0.43 |

6 | 150 | 4.12 | 105 | 1 | 25.4 | 65 | 0.98 | 0.56 |

8 | 200 | 5.38 | 137 | 1.25 | 31.8 | 135 | 0.98 | 1 |

(二)标准的额定流量系数- 4-阶 流量特性:近似线性

公称通径 | 阀座直径 | 额定行程 | 阀内件型式A | 阀内件型式B | 阀内件型式C | 最小额定流量系数Cv | ||||||

Inches | DN | Inches | mm | Inches | mm | Cv | FL | Cv | FL | Cv | FL | |

1 | 25 | 0.7 | 17.8 | 0.25 | 6.35 | 1 | 0.996 | 1.4 | 0.994 | 1.7 | 0.991 | 0.04 |

1.5 | 40 | 1 | 25.4 | 0.25 | 6.35 | 1.9 | 0.996 | 2.5 | 0.994 | 3.2 | 0.991 | 0.08 |

2 | 50 | 1.5 | 38.1 | 0.38 | 9.65 | 4.5 | 0.996 | 6 | 0.994 | 7.5 | 0.991 | 0.12 |

3 | 80 | 2.25 | 57.2 | 0.62 | 15.7 | 10 | 0.996 | 13 | 0.994 | 16.5 | 0.991 | 0.2 |

4 | 100 | 2.88 | 73.2 | 0.75 | 19.1 | 16.5 | 0.996 | 22 | 0.994 | 28 | 0.991 | 0.35 |

6 | 150 | 4.12 | 105 | 1 | 25.4 | 34 | 0.996 | 45 | 0.994 | 56 | 0.991 | 0.46 |

8 | 200 | 5.38 | 137 | 1.25 | 31.8 | 70 | 0.996 | 90 | 0.994 | 115 | 0.991 | 0.8 |

(三)标准的额定流量系数- 6-阶 流量特性:近似线性

公称通径 | 阀座直径 | 额定行程 | 阀内件型式A | 阀内件型式B | 阀内件型式C | 最小额定流量系数Cv | ||||||

Inches | DN | Inches | mm | Inches | mm | Cv | FL | Cv | FL | Cv | FL | |

1 | 25 | 0.7 | 17.8 | 0.25 | 6.35 | 0.8 | 0.998 | 1 | 0.997 | 1.4 | 0.994 | 0.03 |

1.5 | 40 | 1 | 25.4 | 0.25 | 6.35 | 1.4 | 0.998 | 1.8 | 0.997 | 2.5 | 0.994 | 0.05 |

2 | 50 | 1.5 | 38.1 | 0.38 | 9.65 | 3.5 | 0.998 | 4.5 | 0.997 | 6 | 0.994 | 0.08 |

3 | 80 | 2.25 | 57.2 | 0.62 | 15.7 | 7.5 | 0.998 | 9.5 | 0.997 | 13 | 0.994 | 0.13 |

4 | 100 | 2.88 | 73.2 | 0.75 | 19.1 | 12 | 0.998 | 16 | 0.997 | 22 | 0.994 | 0.22 |

6 | 150 | 4.12 | 105 | 1 | 25.4 | 25 | 0.998 | 33 | 0.997 | 45 | 0.994 | 0.3 |

8 | 200 | 5.38 | 137 | 1.25 | 31.8 | 50 | 0.998 | 65 | 0.997 | 91 | 0.994 | 0.65 |

七、汉德多级降压高压加氢角阀型号编制办法 / Model compilation method

HD | 8 | P | 86 | H | 2500 | C | 6 | P | 2 |

厂家 代号 | 阀门 类型 | 驱动 形式 | 阀门 代号 | 密封 形式 | ■ | 公称 压力 | 阀体 材质 | ■ | 降压阶(级)数 | 阀芯类型 | 公称 通径 |

HD/ 汉德 | 8/直行程调节阀 | P/气动 HY/液动 A/气液 E/电动 | 86/多级降 压高压加氢角阀 | H/硬密封 X/软密封 H(X)/软硬密封 | (磅) 或MPa | C/碳钢 P/不锈钢 R/铬钼钢 | 3 /三阶(级) 4 /四阶(级) 6 /六阶(级) | P/平衡式阀芯 N/非平衡式阀芯 | ″ 或 mm |

示例:如选择公称通径为2″,公称压力为2500LB,阀体材质为WCB,平衡式 6阶降压阀芯,硬密封阀座结构,气动薄膜执行机构的汉德直行程系列多级降压高压加氢角阀的产品编号为:HD8P86H-2500C-6P2。

八、订货须知:(见附表三:数据表)balance Nonequilibrium

1、型号;公称通径*阀座直径;公称压力;法兰连接形式;

2、流量特性;执行机构型号;供气压力;

3、阀作用形式(气开or气关)

4、附件要求(定位器、减压阀、手轮等)

5、正常流量和要求最大流量;

6、介质名称、温度、比重、阀前、阀后压力(对应最大or最小流量时的)

7、介质粘度,是否有悬浊液,浓度,颗粒大小)。

ordering information: (see table three: data sheet)

1、type; nominal diameter * valve seat diameter; nominal pressure; flange connection form;

2、flow characteristics; the implementation of the model; gas pressure;

3、 valve action form (gas or gas)

4、 annex requirements (locator, valve, hand wheel, etc.)

5、 normal flow and maximum flow rate;

6、 the media name, temperature, specific gravity, pressure (corresponding to the maximum or minimum flow)

7、 whether the suspension, medium viscosity, concentration, particle size).